Technical Support

- 2015-06-16 15:46:34

-

Are you intending buying a digiat UV flatbed printer for your business? Then you should consider several aspects of the printer before you make the decision. This passage will help you make sense of the complex structure of the printer and have a more professional vision of selecting a flatbed printing machine.

1. The printer body represents the durability and affects the bearing weight of substrates at some extent. In the market, most manufacturers adopt all-steel frame design with powerful and stable table absorbing holes. So the large and heavy substrates can be placed onto the table tightly and no movement of substrates during the printing process can be ensured. For a qualified digital UV flat printer, the details of table absorbing holes and the graduation ruler are very precise. A robust body can be said as the foundation of a good quality flatbed printer.

2. The print heads are very vital for flatbed printers. The print heads are composed of many tiny nozzles whose sizes are nearly as small as particles of dust. The particles of dust or some other debris can clog the print heads and lead to problems of the ink ejection. A high quality print head can be used for one or two years, normally based on the good regular maintenance of the printer.

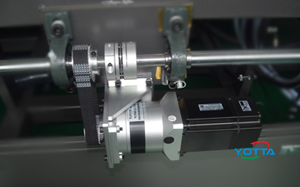

3. The quality and stability of motors are important. Motors are responsible for the belt to carry the carriage moving from one side to the other during the printing process, if the motors are poor, the movement of carriage will not be stable and the print result can be directly influenced. Many manufacturers of digital flatbed printers apply high quality servo motor and rack and pinion drive system to ensure accurate printing process.

4. To detect and control the working status of the printer, different types of sensors are set up in the printer, which including the initial position sensor of carriage, ink cartridge sensor, height sensor and so on. The initial position sensor keeps the print head on the cleaning sponge and ensures the moist of nozzles while the printer is not working. The height sensor measures the thickness of media automatically and adjusts the head gap, and it also protects the print head from collision with substrates. Conducting a test printing will help us know better about the performance of different sensors.

5. One prominent feature of a flatbed UV printer is its UV LED curing system. The development and advantages of UV LED light prompts the printer to deliver photorealistic images with sharp texts and high density colors onto various substrates. The high intensity UV light cures the ink into solidification within a fraction of a second, which notably enhances production efficiency. The UV-LED system generates less heat on the media surface and makes it easier to print onto heat-sensitive substrates. What’s more, no warm-up time is required and it can be switched off and on immediately, and the average lifespan of a UV LED lamp is thousands of hours. Without or with little organic solvent volatile, the UV LED lamps are more ecological friendly. So, to observe the stability and working status of UV LED lamp is pretty necessary.

If all the points mentioned above perform well, we can say the printer is qualified and the durability of the printer will not be poor under normal circumstance.

- Previous [Return Home] [Print] [Go Back] Next

Products Search

Contact Us

Contact Person:

Sales DepartmentTel:

+86-755-89915058Fax:

+86-755-89621558E-mail:

peter@yottaprinter.com