Home > News > Industry News > UV technology will become the first choice for more and more label printing business

Industry News

UV technology will become the first choice for more and more label printing business

- 2016-09-19 16:29:52

-

The global demand for UV printing is rising, especially in Europe, the United States and Latin America. According to equipment manufacturers in Europe, the models of digital UV printers will be growing at an annual rate of 7%, while UV drying devices will be growing at annual rate of 10%, UV inks and coatings will have the faster growth rate of up to 14%. According to the larger ink manufacturer, the local consumption of UV inks and coatings will be increasing about 15% every year, and this figure is almost 10 times the annual growth rate of the traditional offset printing ink supplies.

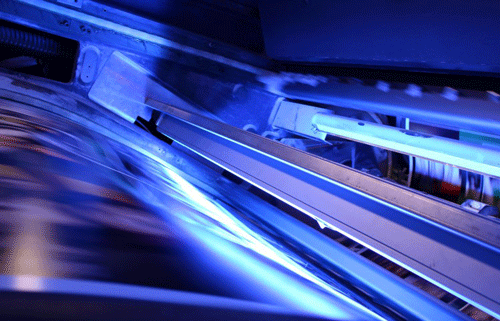

The applications of digital UV printing technology are also constantly expanding, such as labels, plastic, multifunctional sheet and tape printing etc., especially in the field of label printing, UV printing is reflected in unprecedented growth. High-speed flexo labels, shrink sleeve packaging, thermoformed packaging , special effects labels and so on, are printed with UV technology now. We can describe this situation from the high speed curing, low thermal effect, wide rang of substrates and high solids content of UV technology.

The applications of digital UV printing technology are also constantly expanding, such as labels, plastic, multifunctional sheet and tape printing etc., especially in the field of label printing, UV printing is reflected in unprecedented growth. High-speed flexo labels, shrink sleeve packaging, thermoformed packaging , special effects labels and so on, are printed with UV technology now. We can describe this situation from the high speed curing, low thermal effect, wide rang of substrates and high solids content of UV technology.1. UV technology has high speed curing

Flexo is the main printing process for labels printing for lots of advantages. With the high speed of flexo printing, UV curing efficiency has become the key to success. Common infrared drying process is far from meeting the requirements, large baking equipment and lengthy drying tunnel is a nightmare for printing companies. Employing UV curing, inks can be cured within a few second after the printing. It significantly improves production efficiency, as well as omits the baking process. Also, the simple drying device is space saving, suited to high-speed flexo printing of labels.2. UV technology has low thermal effect

Heat-Shrink Label is an important part of label markets and It is now in rapid growth, which requires high technology in production, especially how to control the drying temperature. For ordinary water-based and solvent based inks, too high drying temperature will cause thermal shrinkage and too low drying temperature will lead to tackiness for incomplete drying. Therefore, the process is quite complex, and high rejection rate. For UV drying technology, inks cure rapidly under the irradiation of ultraviolet light and won’t affect the media temperature. It’s unique cold-curing system is ideal for heat sensitive label materials.3.Wide rang of substrates for UV inkjet printer

With the extensive application of labels, printing medias are increasingly used such as PE film, PVC, PP, metal foil and non absorbent materials etc., which are not absorb ink. If using common solvent-based inks, some drying time is needed, usually it requires dusting, drying rack unit or other additives added in the ink. However, with UV ink, it is no such problems. As long as the printing material can be placed in UV inkjet printer, you can finish it. Printed materials can be applied such as: paper, film, PE, PET, PP, OPP, BOPP, PVC, acrylic, plastic, glass, wood, ceramic tile and so on.4.High solids content for UV printing inks

Generally, solids content of solvent-based ink is about 40%, but solids of UV curable ink is close to 100% after being cured. UV ink is very suitable for labels printing with its thick ink layer and bright colors. What’s more, it can produce grating, relief, 3D and other special printing effects by controlling the thickness of the ink layer. Besides, UV technology is also acclaimed in pressure -sensitive table printing. Use ordinary ink on a device with a UV drying unit, substrate can be printed first and bronzed after. Bronzing patterns is not restricted in design. It is suitable for high-end labels printing.In short,with its benefits, we can believe that UV technology will become the first choice for more label manufacturing companies in the near future.

- Previous [Return Home] [Print] [Go Back] Next

Products Search

Contact Us

Contact Person:

Sales DepartmentTel:

+86-755-89915058Fax:

+86-755-89621558E-mail:

peter@yottaprinter.com