Technical Support

UV printing on glass

- 2017-05-06 17:50:43

-

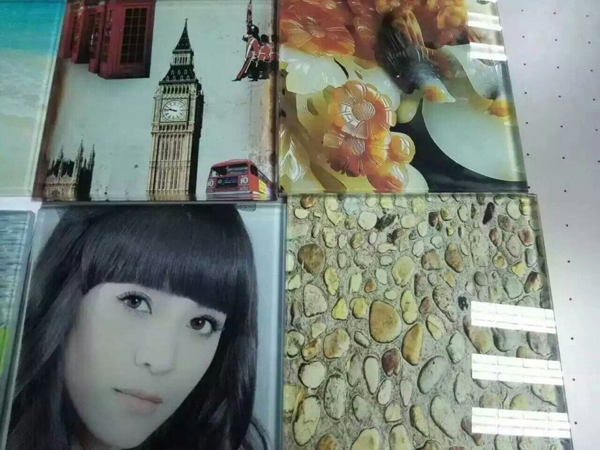

The development of digital UV printing technology opened up new opportunities for printing company to print on a variety kinds of substrates. In the past, imaging on glass was mainly achieved by painting, carving, screen printing. And now, it can be easily achieved by UV inkjet printing technology.The most outstanding advantage of glass printing is that it can get high-end and high-quality colorful appearance. In addition, although one of the biggest use of glass printing is retail goods, it has been more and more widely applied in building, engineering, interior design and more.

The originality of printing on glassBy glass printing, artists can better show their arts. They can show and sell their arts with dining table, coffee table, shower door, glass plate and so on, combining these items with artistic expression. With the development of UV printing, they found a new canvas.Nowadays, another popular way is to printing unique glass architectural signs used in office and reception area.UV printing process of glassPainters and interior designers found that back printing of glass is a very effective way to protect the product with the glass itself, and no need to use tackifier.UV-LED curing technologyThe success of printing on glass depends on excellent adhesion and binding capacity. When printing with UV-LED printing technology, there are three methods that can be used to improve adhesion.The first method is to rub the primer. This method requires the primer to be coated on the entire surface of the glass, preferably with a lint-free cloth, but the appearance of primed surface will be dark and dull.The second is to use printer to print primer to the desired place accurately, and it doesn’t need other wiping or polishing process.The third is plasma treatment. First, it is necessary to remove all kinds of surface impurities, such as dust or residue leaved by solvent detergent. At the same time, it can produce a surface that is more conducive to the surface with the ink.

The originality of printing on glassBy glass printing, artists can better show their arts. They can show and sell their arts with dining table, coffee table, shower door, glass plate and so on, combining these items with artistic expression. With the development of UV printing, they found a new canvas.Nowadays, another popular way is to printing unique glass architectural signs used in office and reception area.UV printing process of glassPainters and interior designers found that back printing of glass is a very effective way to protect the product with the glass itself, and no need to use tackifier.UV-LED curing technologyThe success of printing on glass depends on excellent adhesion and binding capacity. When printing with UV-LED printing technology, there are three methods that can be used to improve adhesion.The first method is to rub the primer. This method requires the primer to be coated on the entire surface of the glass, preferably with a lint-free cloth, but the appearance of primed surface will be dark and dull.The second is to use printer to print primer to the desired place accurately, and it doesn’t need other wiping or polishing process.The third is plasma treatment. First, it is necessary to remove all kinds of surface impurities, such as dust or residue leaved by solvent detergent. At the same time, it can produce a surface that is more conducive to the surface with the ink.

- Previous [Return Home] [Print] [Go Back] Next

Products Search

Contact Us

Contact Person:

Sales DepartmentTel:

+86-755-89915058Fax:

+86-755-89621558E-mail:

peter@yottaprinter.com