Industry News

- 2015-06-10 16:27:35

-

We have talked about the upper half of the history of printing last time, and we continute here.

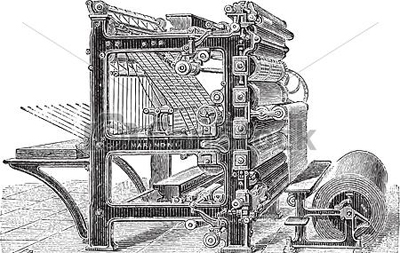

Rotary printing:

Based on the Friedrik Koenig’s steam-powered printing press invented by 1812, Richard March Hoe, who grew up in a family that owned a printing manufactory, had developed and invented the steam-powered rotary printing press in the year of 1843. When printing with this machine, the paper was supported by one cylinder and the other prints plates onto the paper. Thus, the print efficient can be remarkably increased and the costs be cut at the same time. It promoted the spread of information and culture communication and accelerated the pace of printing industry. It is still regarded as the foundation and basis of modern printing machines.

Printing press with automatic paper rollers:

Learned from Richard March Hoe, American inventor William Bullock in 1863 developed a printing press with self-feeding paper rollers, which allowed for continuous large amount of papers to be fed without hand-feeding. The self-adjusting press printed texts onto paper on both sides, and a sharp serrated knife also played an important role since it optimized precision. It provided prototype of advanced and modern automatic-feed printing machines.

Linotype machine:

The linotype machine, the first printing machine that could place entire lines of texts for printing, was developed in 1884 by a German-born inventor named Ottmar Mergenthaler. This machine drastically sped up the printing process and flourished the newspaper industry since it eliminated previous labor-intensive work that required operators to set type by hand one letter at a time.

Monotype machine:

Tolbert Lanston, who was born in a poor family, had successfully developed a method for easier setting up and justifications of the print lines- the monotype machine. This type-setting system was patented in 1887.

A monotype machine was consisted of monotype keyboard and casters. With flexible configurations like removable keyboard and replaceable key-tops, the justifications and corrections of texts became easier than ever, since people could remove a single letter rather than retype a whole line.

Screen printing:

The screen printing is a print method which can place inks through a screen onto any type of substrates, and it is basically a stencil technique. A screen or a mesh and a stencil are necessary when applying this technique. The earliest application of screen printing was in China dates back to A.D. 960 (during the Song Dynasty), and it has been greatly developed in Western countries around the mid-20th century. The significant breakthrough of this technique is its capability of producing high quality images with brilliant colors onto all types of plastics, metals, textiles, leather, glass, papers, ceramics, woods, and so many more. Thus, it can be applied in many industries and it occupies an extremely important position in modern printing industry.

Xerography (Electrophotography):

Inspired from the physical principle that materials of negative and positive charge attract each other, an American patent lawyer called Chester Carlson invented xerography in 1938, which combined electrostatic printing with photography and started the office copying revolution since its appearance. The process can mainly be divided into six steps: charge, expose, develop, transfer, fuse and clean. The toner is negatively charged by the image on the drum, and then attached to positively charged paper. Proper heat and pressure are used to make the toner to permanently adhere to the paper. However, as the toner on the paper is not 100 percent efficient, the residual toner must be cleaned.

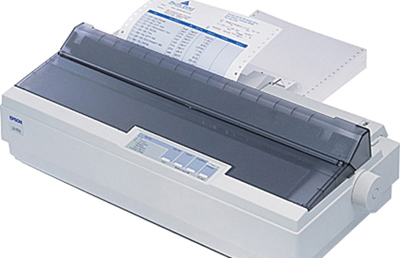

Dot matrix printing:

Dot matrix printing is a type of printing technology which produces images or characters by striking pins over an ink-soaked ribbon. Varied fronts of characters and shapes of images can be delivered. The first dot matrix printer was invented in the early 1970s, and it had been commonly used in homes and offices. The print quality of it is associated with the number of pins, which can be varied from 9 to 24, the more pins, the better the print quality. Its low purchase cost and the ability of printing on continuous paper wined favors from people, but some drawbacks of it made it be gradually substituted by other types of printers, such as the noise and low resolution prints.

Inkjet printing:

Inkjet printing is a printing method which connects to the computer and uses a series of nozzles to eject small droplets of ink onto substrates to produce images or texts. The concept of it appeared in the 19th century and it was extensively advanced around the mid-20th century for better computer graphics output and reductions in costs. Two main technologies are applied to inkjet printing: the continuous inkjet and drop-on-demand. Main components of an inkjet printer include the print body, print head, ink cartridges, stepper motor, belt and stabilizer bar and so on. Inkjet printers have gained great popularity because of its outstanding performance, humanized convenience, flexible ink configurations and low costs etc.

Dye-sublimation printing:

Dye-sublimation printing is a digital printing technology that requires heat to transfer image onto materials. A dye-sublimation printer allows high resolution, bright color images that will not fade or crack from the substrate. Being able to deliver continuous tones, it is your preference when dealing with photographic prints and ID cards and many other high-end prints. Compares with the inkjet printer, the dye-sublimation printer creates ink droplets with any color, while the former one is limited to the ink colors of each drop. However, a dye-sublimation printer is generally more expensive and less practical for home and common use.

Laser printing:

The basic technology of laser printing was originated from xerography, whose primary working principle was static electricity. It produces high quality images and texts by projecting a laser beam onto the electrically-charged photoreceptor drum, and the printing process is more quickly than xerography printers. The first laser printer was invented in 1969 by Gary Starkweather, and laser printing technique had been further developed through companies like Canon, HP, IBM and others for the decades.

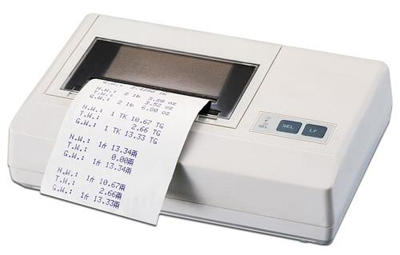

Thermal printing:

Thermal printing is a type of technique which involves heating and pressure element to create images and patterns onto special treated paper-thermal paper. The main components of a thermal printer are thermal head, platen, spring and controller boards. A thermal printer requires no ink and it tends to be more economic and affordable for many retail applications. Comparing with dot matrix printer, the thermal printer has less noise and usually faster with efficient heating mechanisms. Thermal printer has been widely used in POS terminal systems, banking systems, medical equipment and other fields.

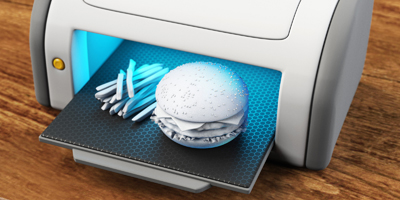

3D printing:

3D printing is a process of making three-dimensional solid objects that created by placing successive layers of material according to a digital file (CAD file). The materials are limited (usually are plastic, ceramics and metal) and this kind of limitation determines 3D printing is not able to produce complex objects like sophisticated electronic equipment. However, it still benefits the world. Take the medical industry as an example, with this technique, skull pieces and ear molds can be created and used for patients. The invention of 3D printer happened in the 1980s. In 1981, Hideo Kodama invented two methods of a three-dimensional plastic model. Chucks Hull of the company “3D Systems” invented the first commercial 3D printer in 1986.

Digital printing:

Digital printing includes many modern printing techniques such as laser printing and inkjet printing. It means print images or texts directly onto a large array of substrates with digital files, including TIFF, BMP, PDF, EPS, JPEG and so on. The price of a digital printer is usually higher than conventional printers. But we should be aware of the benefits that a digital printer has brought to us. Printing with a digital printer means the creating of plates is not required anymore; it also fastens turnaround time and improves the print results. Instead of printing with large quantities, on demand printing for as little as one print can be achieved. So we can get the conclusion that the considerable savings in labor and time of a digital printer, such as an inkjet printer, are substantially reducing the production costs and prove an inkjet printer is more cost-effective than any other conventional printers.

With the development of various technologies, the industry of printing certainly will be progressively advanced and prosperous and will demonstrate many more surprises and conveniences to the world.

- Previous [Return Home] [Print] [Go Back] Next

Products Search

Contact Us

Contact Person:

Sales DepartmentTel:

+86-755-89915058Fax:

+86-755-89621558E-mail:

peter@yottaprinter.com