Technical Support

- 2019-01-04 10:03:19

-

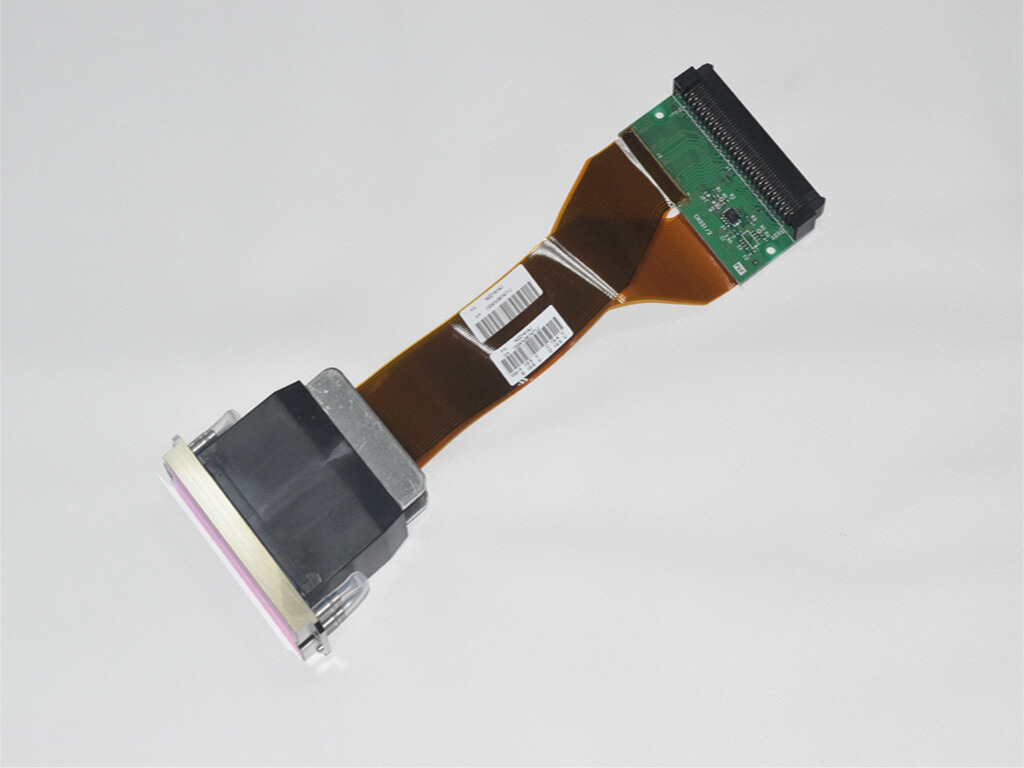

UV printer 7 points by maintenance, 3 points by quality, It is an important technical activity to clean uv printerhead in the maintenance of uv printers. Properly master the cleaning method of the printhead, which can maintain the printerhead well, effectively extend the service life of the printhead and reduce the depreciation cost of the equipment. The cleaning liquid is generally used when the printhead is blocked. So how to use the cleaning liquid correctly and what problems should be paid attention to during the cleaning process?

Clean the printhead method, please click here: https://youtu.be/iVlMa4iHH3g

1. Immersion method

Scope of application:Lightly blocked

Instructions: Prepare a small flat plate, place the print flat on the plate, and then inject the special cleaning liquid of the uv printer into the plate, The depth is determined by the portion of the printhead that has just been immersed. Be careful not to spill cleaning liquid on the cable plug and drive board. The first soaking time is about 1 to 4 hours.

2. Printhead injection flushing

Scope of application: heavier blocked

Instructions: Install the cleaning liquid with a syringe, and press the cleaning liquid in the syringe into the printhead through the filter connected to the printhead. Note that the pressure should not be too large to avoid squeezing the waterproof separator inside the printhead. This process needs to be repeated several times until it is seen that each of the ink discharge holes ejects a fine cleaning liquid. In this way, the blocked printhead is completely cleaned.

3. Ultrasonic instrument cleaning method

Scope of application: Severely blocked

Instructions: Gently put the inkjet print head into the washing machine and add the UV printer cleaning liquid. The cleaning liquid is just enough to cover the stainless steel edge of the print head (be careful not to let the pcb board touch the cleaning liquid), and it can be turned on for 10 to 15 hours. Clean quickly. The advantage is that the cleaning effect is very good, the print head that has been blocked for many years can be cleaned and the operation is very simple; the disadvantage is that the maintenance cost is high and the price is relatively expensive.

- Previous [Return Home] [Print] [Go Back] Next

Products Search

Contact Us

Contact Person:

Sales DepartmentTel:

+86-755-89915058Fax:

+86-755-89621558E-mail:

peter@yottaprinter.com